Asset Management Manual

A guide for practitioners!

Asset Management Manual

A guide for practitioners!

BEN HELSEN, Flemish Roads and Traffic Agency (AWV) - EMT, Belgium

The IIR (Inventory, Inspection and Reporting) project was started within the Flemish roads and traffic agency (AWV) in 2012, with a view to achieving efficient inventorying and inspection of road accessories (both electrical equipment and the actual road accessories, as well as road condition).As part of the group of electromechanical facilities, sign gantries for dynamic traffic management (DTM) were included in the project right from the start, mainly on account of their potential risk (position above the carriageway).

The electromechanics and telematics (EMT) division of AWV – more specifically its traffic enforcement systems (VHS) team, which also provides the operational management of those facilities – was placed in charge. The objective of AWV is to take a detailed inventory of the full asset in place. Newly installed facilities (e.g. in new construction projects) are added to the inventory as standard procedure.

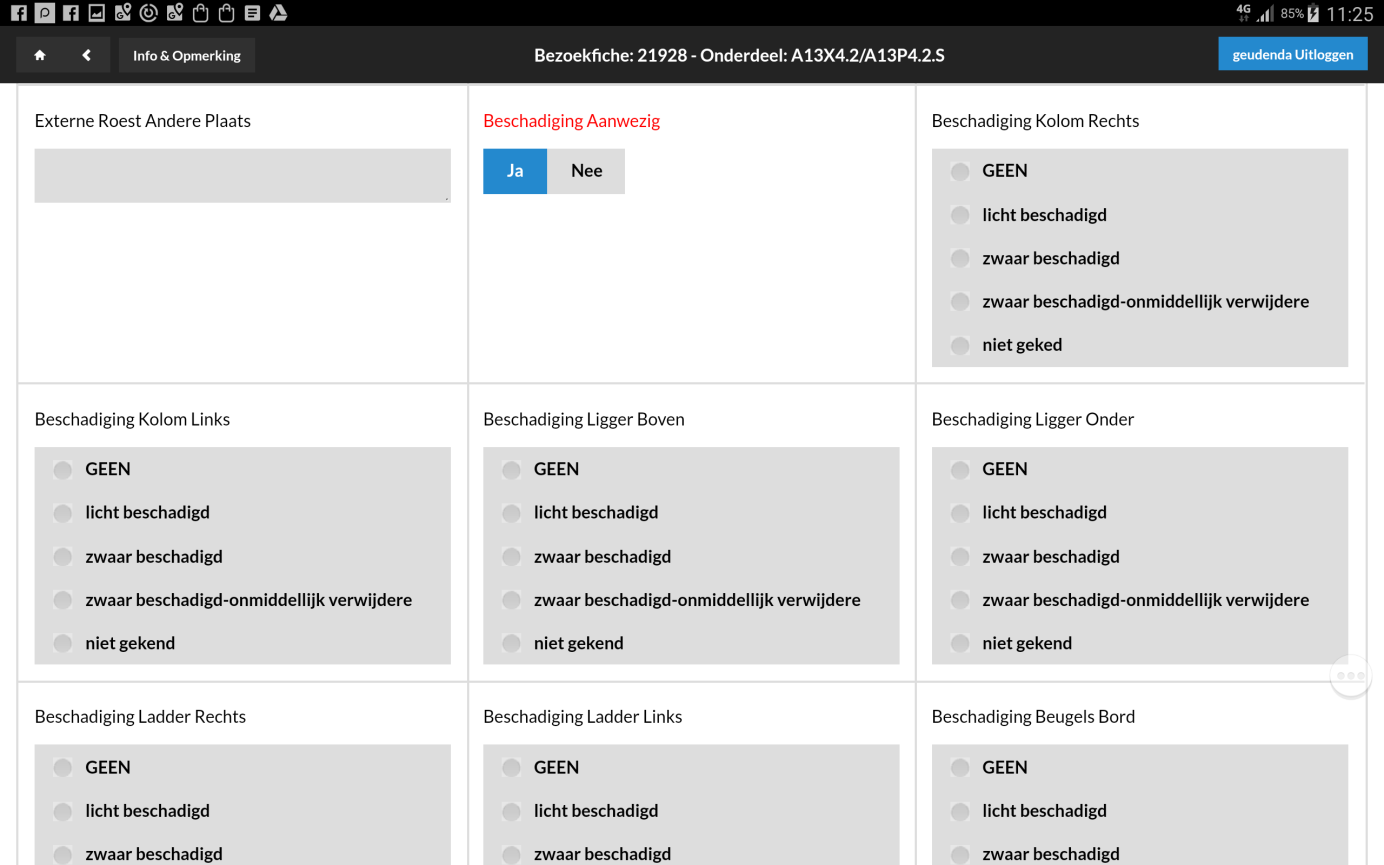

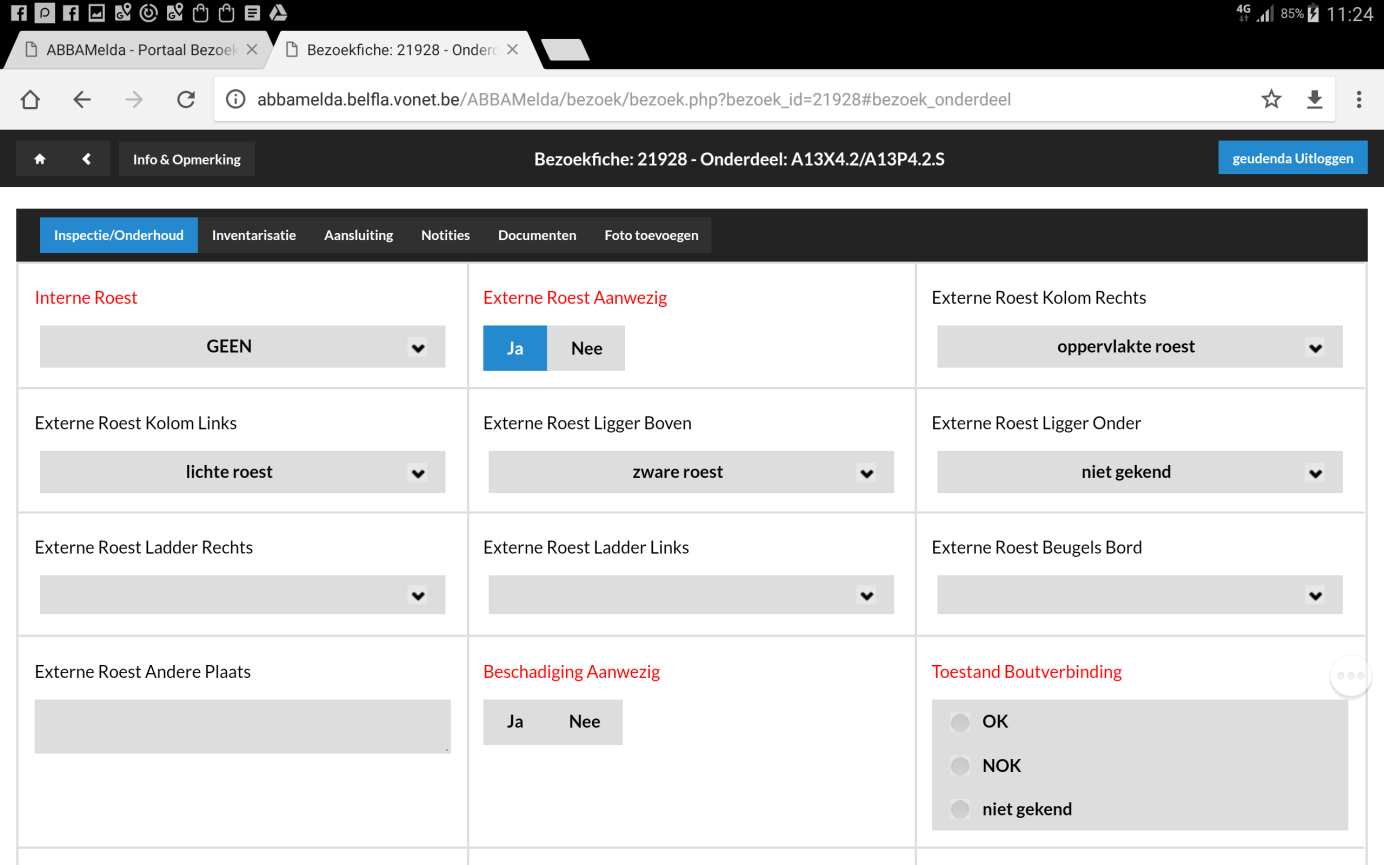

The inspections include assessing and recording the condition of the facility, with special focus on stability, corrosion and the condition not only of the columns, but also of the clamps and bolts.

The approach is a basic solution to manage the maintenance risk of electromechanical facilities, sign gantries for dynamic traffic management (DTM) on the Flemish roads.

Efficient inventorying and inspection of road accessories. The objective of AWV is to take a detailed inventory of the full asset in place.

The inspections include assessing and recording the condition of the facility, with special focus on stability, corrosion and the condition not only of the columns, but also of the clamps and bolts.

Structured detailed inventory of the asset (of DTM sign gantries in this case), with a representative inspected status of both the entire facilities and their relevant parts. Using this inventory, status reporting makes it possible not only to define an adequate maintenance policy but also to take targeted remedial (or, if necessary, proactive) measures through the maintenance programme – which is otherwise mainly directed to operationality – or, if necessary, through well-advised targeted (re-)investments.

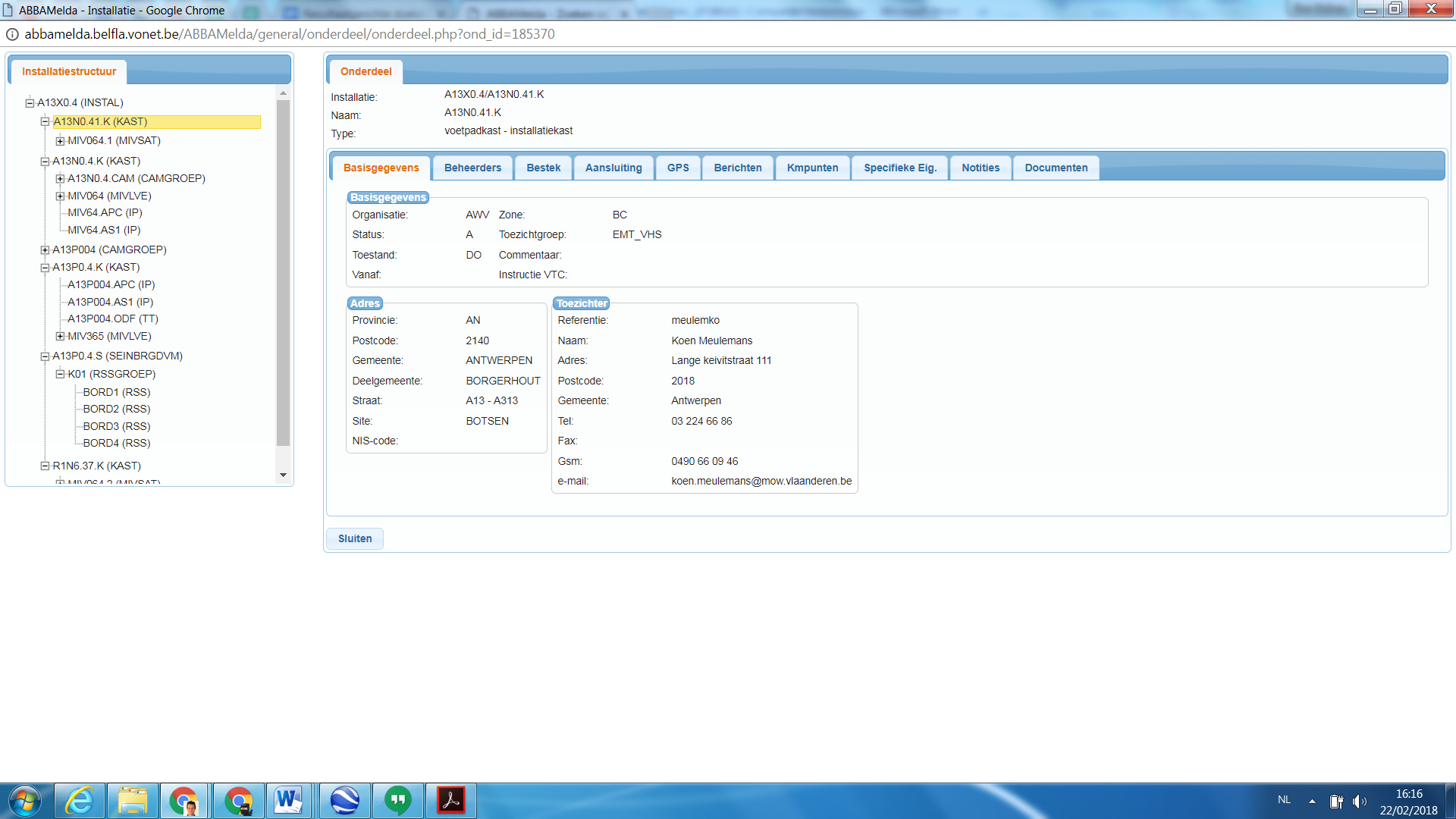

Before the IIR project, AbbaMelda was already a first form of asset management, at least as far as the electromechanical facilities managed by AWV’s EMT division were concerned. However, it was a rather single level and little structured listing of facilities mainly intended for use in calling up the contractors concerned in case of defects or damage and in recording the calls and their handling. Moreover, the listing was high-level as far as the facilities were concerned, with little on no specification of component parts and, consequenly, few or no interrelations.

A safety incident triggered the setting up of the IIR project, which built on the existing AbbaMelda data base for electromechanical facilities such as DTM sign gantries.

The facilities already included were renamed in many cases, but also – and mainly - often merged into coherent logical sets. Many more component parts were specified and included (e.g., not only the sign gantry with variable message signs, but also the individual signs, their controller cabinet and the representative parts inside, and characteristics of, that cabinet. Electric power supply and the communication network were included as well.

Figure 2.1.5.7: AbbaMelda data base for electromechanical facilities

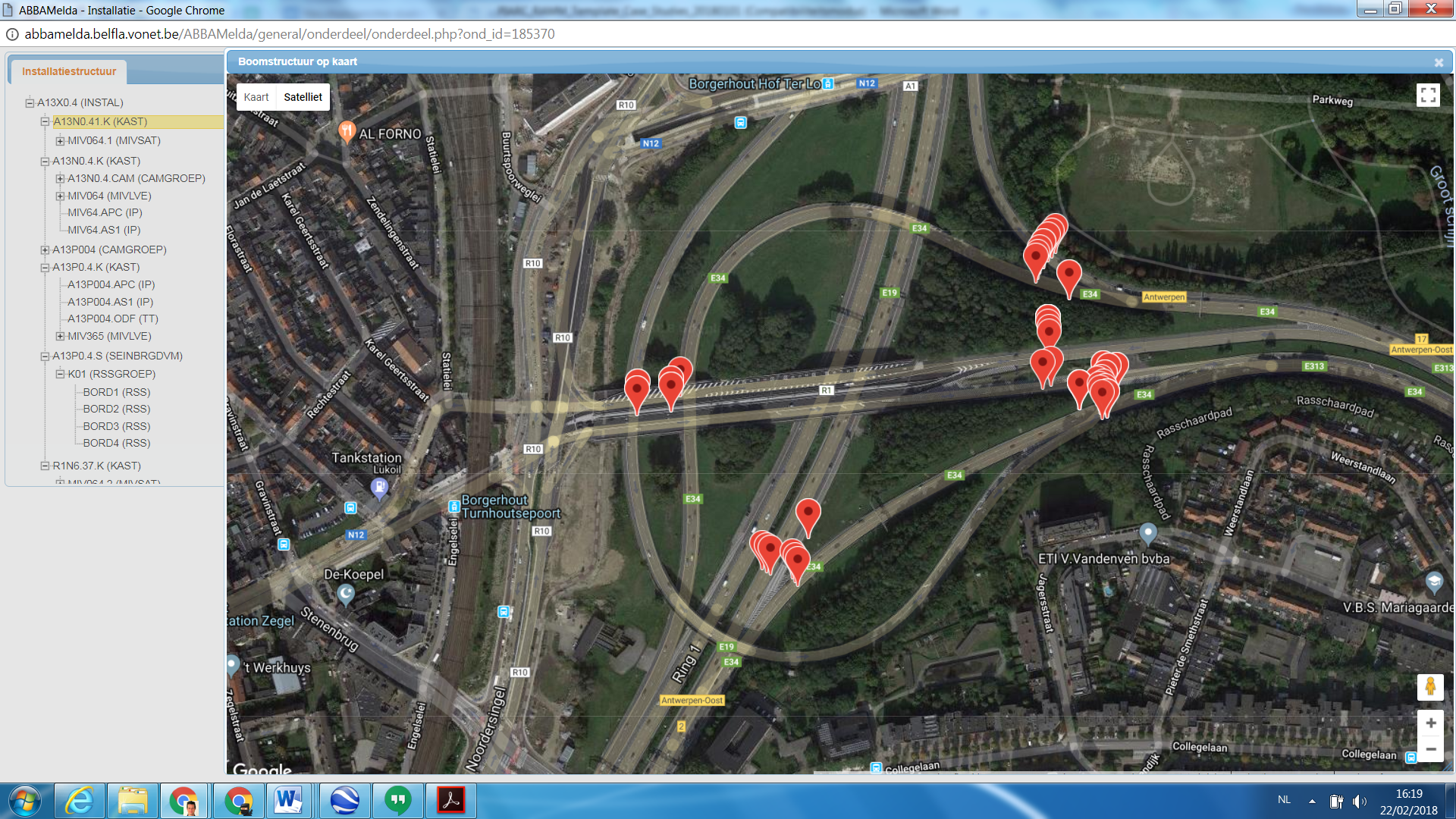

Additionally, maximum accuracy (typically GPS) location data were assigned to the facilities and parts, enabling the data to be coupled in numerous GIS applications for various purposes (e.g., conflict detection in case of scheduled works).

Figure 2.1.5.8: AbbaMelda data base for electromechanical facilities

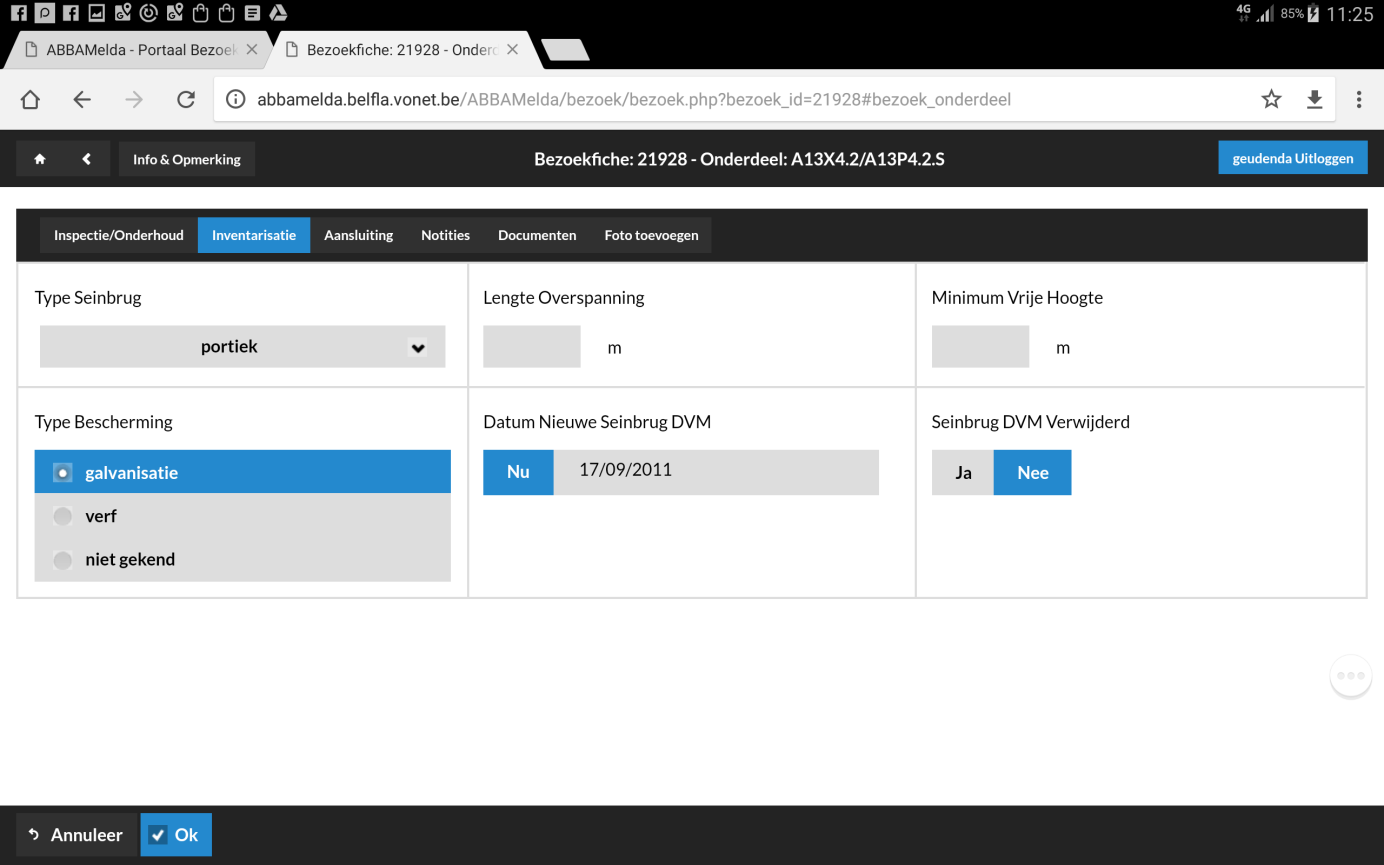

A portal named “Mobiel” was developed for use on a tablet, which made it possible not only to inventory (or continue inventorying) facilities on site, but also, and mainly, to inspect them.

A few screenshots for DTM sign gantries are presented below.

Figure 2.1.5.9: AbbaMelda data base for electromechanical facilities

Figure 2.1.5.10: AbbaMelda data base for electromechanical facilities

Figure 2.1.5.11: AbbaMelda data base for electromechanical facilities

Two new projects were recently started. In the first project, the existing application AbbaMelda is divided into two parts, with the facility database part being renewed into a modern application which not only better suits the functional needs but wil also, and mainly, provide additional possibilities for interrelations, structures, etc. Concurrently, an AIM/BIM-oriented project was launched at AWV level.

Whereas a few years ago AbbaMelda was mainly a tool for recording and monitoring defect repairs, it has developed and is still developing further into a central data base of electromechanical facilities managed by AWV: type of facility, location, interrelations, status, parts, persons in charge, etc.