Asset Management Manual

A guide for practitioners!

Asset Management Manual

A guide for practitioners!

AHMEDABDALLA AL HAMMADI, Ministry of Infrastructure Development, United Arab Emirates, Northern Emirates

In 2013 the Roads Department of the Ministry of Public Works of UAE (currently Ministry of Infrastructure Development, MoID), started the corresponding tasks for the project “Preparation and Operation of Pavement and Asset Management System”, whose object was the implementation of a methodology along with a management system, for the maintenance of the network of roads to its charge. The initial project was carried out from 2012 to 2016, and currently the second phase (2017 – 2019) is under development by the same company (RAUROS), due to the success obtained during the first one.

The projects include different tasks within the road asset management field, related to: condition survey data collection using high performance equipment, pavement condition analysis, maintenance plan analysis, road asset management system (RAMS) implementation and customization, bridges and slopes inventory, app development for routine works control, analysis of new maintenance solutions adapted to UAE road network characteristics and a full time consultancy service in UAE Ministry of Infrastructure Development facilities.

Below is described the work performed during these contracts, having received the first contract the 2015 Global Road Achievement Award in Asset Preservation & Maintenance Management, awarded by International Road Federation during Congress celebrated in Istanbul (Turkey) held in 2015.

The successful of this work is based on the implementation of a preventive system in UAE Ministry of Infrastructure Development procedures adapting it to UAE road network characteristics, the full time consultancy service, and the implementation of a modern, powerful and useful system that allows technicians and manager to make easier and faster decisions, based on technical and economic parameters for achieving an optimum maintenance of the road network.

The network of roads of the Ministry includes freeways, highways and conventional roads, being most of them spread over the north of the country, with an approximate length of 1,300 kilometers of carriageway, equivalent to 2800 kilometers of lane.

In order to schedule a correct maintenance planning, it is crucial to know the road assets that form part of the network of roads. Therefore, the first tasks have consisted of taking a full inventory.

For this purpose, specialized designed equipment was used. Such equipment can take images and other measurements while driving at to more than 70 km/h.

Figure 4.1.6.1: Condition inspection vehicle

All the collected information allows to know the location and typology of the road assets that need maintenance: signage, highlights, guardrails… This inventory allows, to the conservation staff, to drive a correct control of the routine maintenance and schedule all type of inspections.

It is a fact that pavements constitute 80% of the investment required for the maintenance of the network. Therefore, it is necessary to know their condition. For this reason, different tests are performed by using high performance equipment.

Functional and structural characteristics were evaluated. The functional characteristics are tied to the diving surface of the pavements. Four functional parameters are annually measured in the roads of UAE:

Such measurements are obtained through the measure of the transversal profile, by using specific equipment that has several laser devices lined-up. From the transversal profile, the depth of each rut can be calculated.

Besides, there exist some structural characteristics.

The knowledge of the traffic of each one of the roads and its evolution is another key factor. For this purpose, several counting stations to determine the traffic density are being installed in strategic spots within the network. A total of 27 fixed stations are being installed, and 70 measurements of temporary traffic density are being taken. The counting stations count the number of vehicles and classify the data regarding the vehicle typology; they also take measure of its speed. Another essential parameter that needs to be determined is the weight of the vehicles. For this purpose, 5 stations of dynamic weighing (Weight in Motion) are being installed. These devices take measures of the load per axle, information which is absolutely necessary for adjusting the calculations when dimensioning reinforcements in the pavements.

Additionally, a highly detailed inventory of all the bridges, slopes, culverts and camel crossings is being performed. At the same time, basic inspections of each asset are being made. The inventory comprises the geographic location of the structure and the identification of each forming element (typology and material). The geometrical dimensions of each bridge is being also determined. The routine inspection consists of a primary visual identification of possible damages or pathologies that can cause failures in the structure, from the functionality or durability point of view.

Lastly, but no less important, some testing/coring are being made within the whole road in order to perfectly know the cross section of each road, so proper pavement analysis can be made, specially where new materials have been used for rehabilitation purposes.

Once data taking is concluded, in order to manage and take benefit of the huge amount of information collected, it is entirely essential to rely on a proper asset management system.

For this purpose, the choice made by the MoID was ICARO, a comprehensive Road Asset Management System (RAMS) used internationally and which first version was developed more than 15 years ago, made out of the collaborative work of a highly qualified team formed by computing and civil engineers, permanently focused on the needs of technicians and managers of public administrations and highways operating companies of all over the world.

The implantation of ICARO has allowed the MoID to take advantage – by using a single and powerful tool – of all the necessary data to carry out the full management of the road heritage. Such essential information has been provided by means of photographic, cartographic and numerical way, all under total coordination.

Technicians of certain areas within the General Direction of Roads can now study the data aforementioned in a simple way. Additionally, the data can contribute to provide information about road safety (crashes, risk index, etc..), as well as to control the routine maintenance tasks. Such extra information is extremely valuable for any administration of a network of roads.

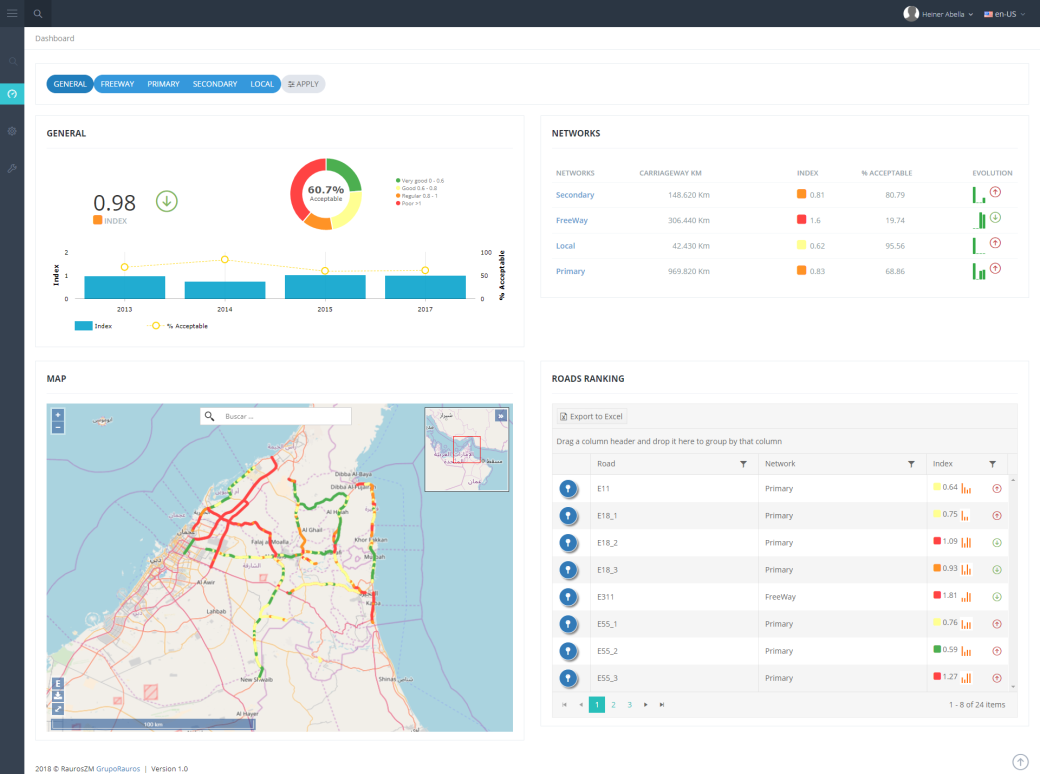

Figure 4.1.6.2: RAMS Screenshot ICARO

To carry out a preventive management is necessary to have a RAMS capable of storing and exploiting a large number of aspects:

In addition to the RAMS, it has been developed an app for the use of mobile devices which allows for georeferential data collection on-site to be later synchronized with the central system. The application has been designed to automatically place itself according to the position the GPS signal receives and to display the inventory asset existing in the system at that kilometric point. It automatically selects the corresponding road and stretch. The application allows reviewing the existent assets, to register the characteristics of them using their own files or to add new inventory assets.

In summary, the MoID can rely on an expert management system that allows:

Definitely, to increase the service standard offered to the users and to decrease its costs.

Knowing the possibilities of investment in the maintenance, determining the quality degree that can be achieved with such investments and defining suitable quality thresholds, the best preventive maintenance system can be attained. For this purpose, it is always necessary to reach the balance between the aim to fulfill and the investment to make. ÍCARO system provides the Ministry with a technical support that clearly justify when, where and how much it is necessary to invest in the maintenance.

This software has been installed in the Ministry offices, and not only the staff located in the Ministry main offices, but also the personnel that works in field, has full access to the system through the app.

All these tasks are being managed by a consultant company, and directed by the Ministry of Infrastructure Development staff,

It is known that one of the indicators of the level of development of a region is, without doubt, the state of its network of roads and roads in the case of a city.

Developed countries apply this preventive management model from the start-up.

At the same time, the regions that are still developing are incorporated into this model as soon as their economic capacity allows them to deal with non-basic aspects.

The preventive management of a network can only be carried out once a certain level of quality has been reached. Before reaching that level, the systems can only help to prioritize the actions. Later, the real preventive management will begin.

The main objective of this management method is to achieve a high degree of commitment to citizens, ensuring that investments will serve to achieve the best maintenance. In order to fulfill it, it is necessary to:

All this, for reaching a balance between the objective to be met and the investment to be made.

ICARO RAMS implemented and described in this case study is simple and powerful, developed by RAUROS for more than 15 years, and implemented in multiple administrations around the world, both private and public.