Lifecycle planning enables the asset managers to assess their decisions from a future oriented and sustainable point of view. There are different methods and solutions how to plan future maintenance activities on different types of assets. Lifecycle planning can be seen as the state of the art for finding the most efficient and adequate maintenance solutions. Thus, it should be applied especially on those assets where a high deterioration affects the different stakeholders.

In the following chapters the method of lifecycle planning as a part of modern asset management are presented. These chapters focus on modelling, planning, investment, resource allocations and procedures for generating a holistic lifecycle plan.

The objectives of lifecycle planning can be summarized as follows (UKRLG and HMEP, 2013):

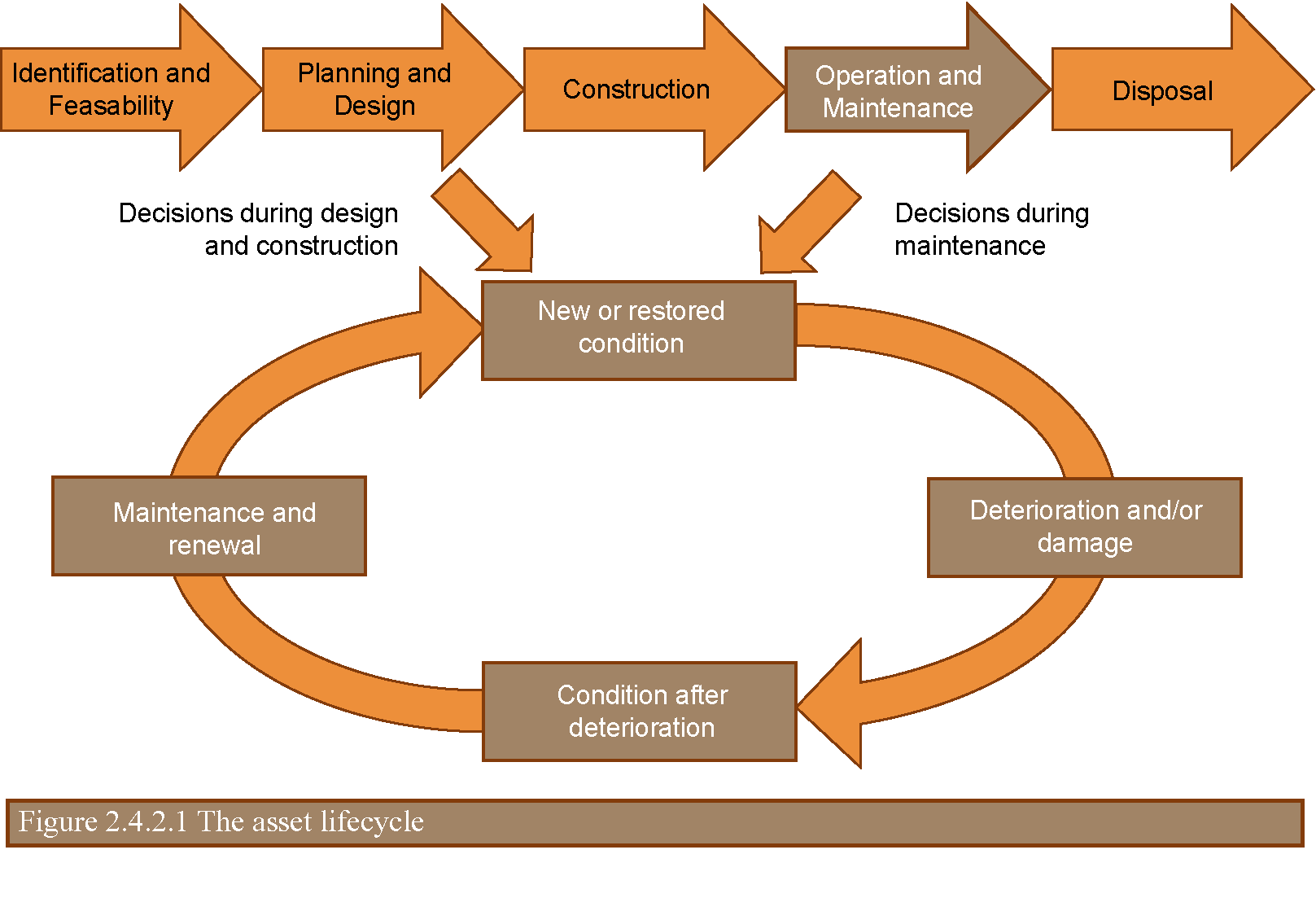

Lifecycle planning describes the approach to maintaining an asset from construction to disposal. It involves the prediction of future performance of an asset, or a group of assets, based on investment scenarios and maintenance strategies. The lifecycle plan is the documented output from this process (UKRLG and HMEP, 2013).

Lifecycle plans may be used to demonstrate how funding and/or performance requirements are achieved through appropriate maintenance strategies with the objective of minimizing expenditure while providing the required performance over a specified period of time (PIARC 2000).

Lifecycle planning can be applied to all road infrastructure assets and can adopt a range of basic approaches depending on the maturity of the organization and the skills and capabilities of its staff. However, its application may be more beneficial to those assets that have the greatest value, require considerable funding, and are high risk and/or seen as critical assets. In some cases, complex approaches may be applied, and in these circumstances, higher quality data and predictive modelling techniques will often be needed. Where minimal data are available, a more basic or a risk-based approach may be adopted, as discussed in section 2.3.

The lifecycle of an asset covers the following stages:

Maintenance strategies may be developed that consider different treatment options and balance renewal with routine maintenance. These strategies should take into consideration the service life for each treatment option and balance the costs over a planned period of time. The objective of this process is to provide a lifecycle plan for an asset that will support the implementation of the asset management strategy and objectives. When applying a lifecycle approach, the following questions may be answered for a short-, medium-, and long-term period of planning for each asset:

Adopting a lifecycle planning approach supports organizations in applying the principles of asset management to set maintenance standards that they can afford and/or that are desirable.

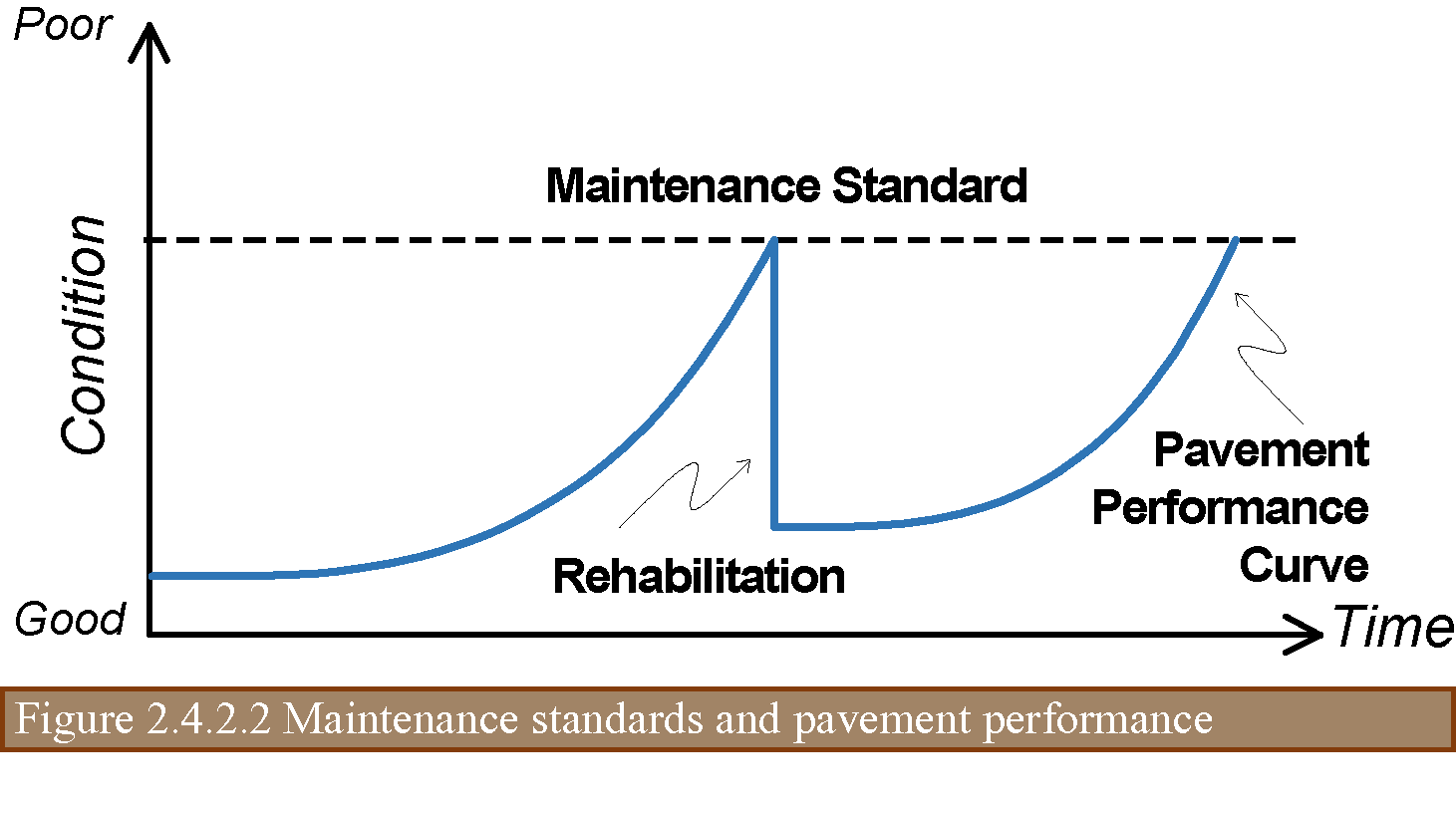

The desired performance is determined by setting the maintenance standards through developing performance targets, as described in section 1.4. Current asset performance is assessed through collecting information and data, based on the approach described in section 2.1, and monitoring performance, as described in section 2.2.

Typically, maintenance standards will have been selected for each asset type or group. These standards would normally represent the maintenance thresholds but may vary depending on the maturity of the organization that is applying lifecycle planning principles. It should be recognized that different performance requirements may also be adopted across different network hierarchies. For example, strategic roads may have different maintenance standards than less trafficked rural roads.

Where assets are to be maintained in a steady state, the lifecycle plan should be developed to meet existing performance requirements, as shown in Figure 2.4.2.2.

The approach to lifecycle planning adopted by an organization should be documented. Documentation should include the assumptions made, performance requirements, maintenance needs, the decision-making process, and the proposed maintenance strategy, including the timing of interventions.

A lifecycle planning approach will enable the maintenance strategy for all assets to be determined. However, the principal assets, where the greatest investment and/or risk will be incurred, should be considered as priorities when resources are scarce. Lifecycle planning is therefore likely to provide the greatest benefits for assets where large investments are made, including carriageways, footways, structures, and lighting.

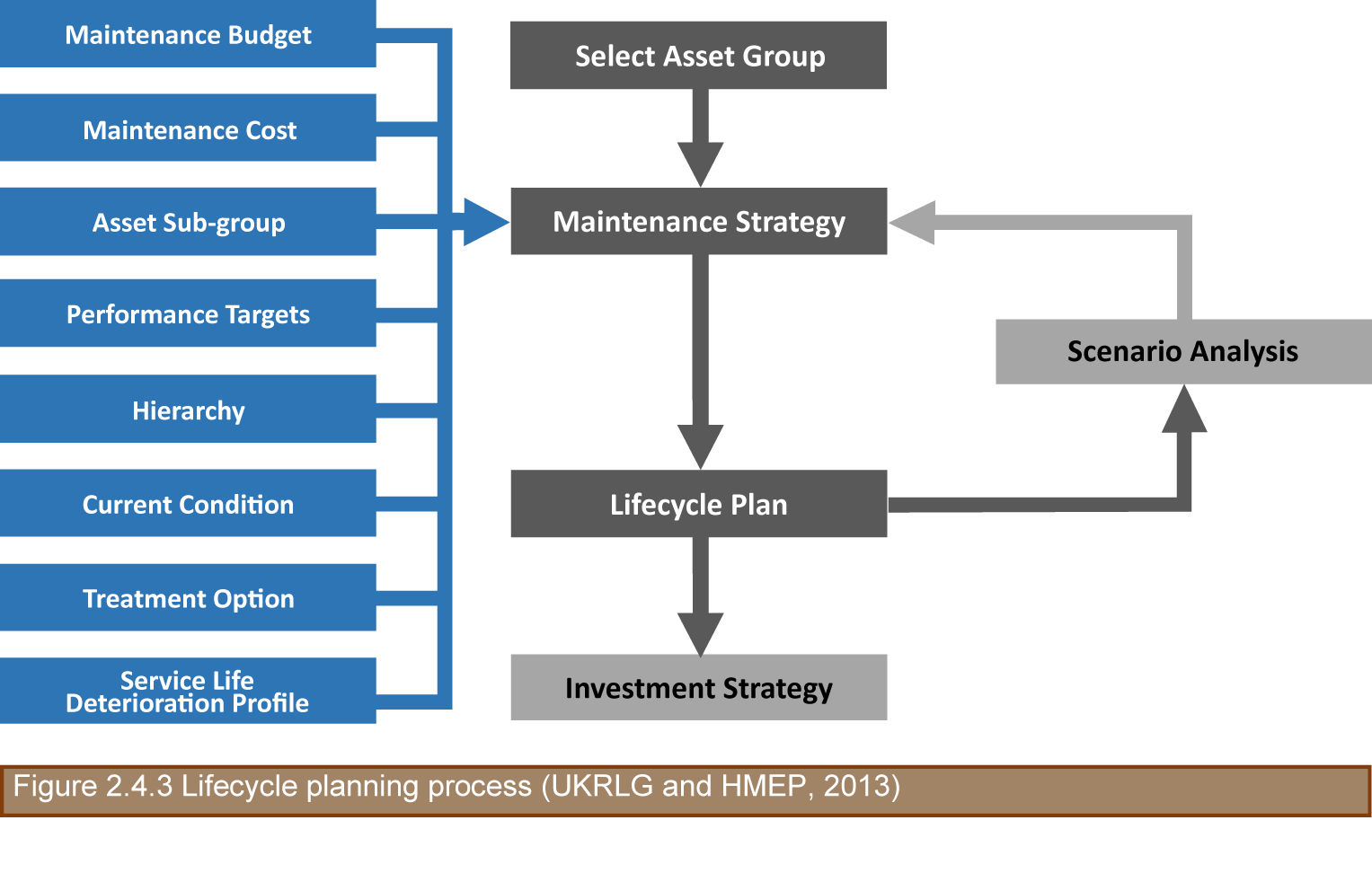

The lifecycle planning process is shown in Figure 2.4.3.

The degree to which each aspect is considered, as well as its sophistication, depends on the organization’s stage of maturity and the benefits it will achieve by investing in a lifecycle approach.

In developing a lifecycle plan, the asset group and/or its components should be identified at the network level, with similar assets grouped and aggregated together. The approach to selecting and grouping assets (see section 2.1) can be summarized as follows:

Asset data for lifecycle planning should be available from the organization via an asset management system, asset register, or maintenance management system (see section 4.1). Typically, the following is required to develop lifecycle plans:

The data requirements for lifecycle planning should be identified as part of the overall approach (see section 2.1). This may require specific data to be collected for relevant asset groups and their components.

The reliability, quality, and quantity of the data available, including inventory data and the historical performance of treatments, should be assessed before developing lifecycle plans. In general, the greater the confidence in the data available, the greater the confidence in the lifecycle plan.

Lifecycle plans should be updated regularly as new asset data becomes available. Plans should also be reviewed against any changes in the approach to asset management.

The inputs for lifecycle planning are as follows:

Asset inventory:This is the number, size, and/or dimensions of the asset that is to be analyzed. For a pavement maintenance project, this will be the length and width of the treatment area.

Analysis period: This is the duration over which the maintenance costs are to be evaluated. It should extend over at least one full lifecycle of the asset/treatment under consideration. Once an analysis period has been selected, it must be consistently applied across all maintenance options that are under consideration. Failure to do so will prevent meaningful comparisons between the lifecycle plans.

Treatment options: A treatment option needs to be selected for the lifecycle plan and can be prescribed for each maintenance strategy. Options could range from small-scale superficial works to wholesale replacement or reconstruction. A range of materials options or specification types should be considered. For a pavement maintenance project, treatment options will likely include a range of treatment depths.

Service life: The service life of an asset or treatment will determine the timing of future maintenance interventions. The use of realistic, achievable service lives is of primary importance in lifecycle planning. Service lives should be determined locally and be based on a number of factors, including performance history, material type, specification (including construction practices and workmanship), local environment, and demand (such as traffic levels and energy consumption, not necessarily applicable to all assets). These factors are based on practical experience, but they could be amended to suit local practices or performance histories.

Unit rates: This is the cost per unit measure (number/length/area/volume) to maintain an asset or part of an asset. It could, for example, be the price per square meter to apply a particular resurfacing treatment to a carriageway or the cost to replace a single lighting column. It is important that the engineer appreciates what is included in a particular rate and is aware of any assumptions that were used in deriving its value. This is considered to be essential to arrive at an accurate works cost.

Works costs: This is the direct cost of undertaking planned maintenance activities on site. Unit rates are used to estimate the works cost. The cost of site establishment, traffic management, and preliminaries should be included.

Routine maintenance costs: These are the (direct) ongoing costs of maintaining an asset in a safe and serviceable condition. These costs exclude cyclic activities such as sweeping and cleaning (because these are normally constant factors that will not vary according to treatment strategies or types). Routine maintenance costs need to be factored into the lifecycle plans if competing maintenance strategies are likely to result in significantly different ongoing costs.

Discount rates: Discounting is a technique used to compare costs (and benefits) that occur at different times throughout the analysis period. It works by adjusting these future costs (and benefits) to their present-day values. This practice enables competing maintenance options to be compared on a common basis, in that once a discount rate has been selected, it must be consistently applied across all maintenance options that are under consideration. Failure to do so will prevent meaningful comparisons between the whole-life costing results.

The outputs from the lifecycle process are as follows:

Investment strategy: The maintenance strategies, timing, and (direct and indirect) costs determined above will enable the production of a profile showing future investment in each year of the analysis period. By analyzing cost profiles across a program of works, it is possible to identify instances in the future where major works on several projects may coincide in a single year. These instances may pose future funding issues (and create network management and workload issues). Alternative maintenance strategies can then be considered to alleviate peak demands.

Discounted works cost: This is the present-day cost of all future maintenance requirements. It provides a basis for comparing alternative maintenance options and indicates the level of investment that will be required to meet future expenditure.

Once the need for maintenance has been identified, the input parameters above can be used to undertake a lifecycle analysis by considering the maintenance strategy to be adopted:

Do Nothing: Under this strategy, the organization would undertake reactive repairs for safety defects only. These repairs are likely to be superficial and would possibly be temporary in nature. The repairs would not arrest the decline of the asset, and frequent revisits are likely to be required. In the short term, routine maintenance costs are likely to be high due to the ongoing liability.

Do Minimum: Under this approach, the organization seeks to do the minimal amount of routine maintenance work to keep the asset safe and serviceable. Works will normally be restricted to the repair of safety defects; repairs will normally be permanent in nature, although they will add no value to the asset. In the context of a pavement project, this approach might be limited to the permanent repair of potholes only. These repairs would be undertaken on an isolated basis or may extend to small patches.

Do Something: This approach is likely to involve capital expenditure by an organization rather than routine expenditure. It may include the wholesale replacement or major repair of an asset to a level that will enhance its long-term durability and minimize future routine maintenance. A proactive approach may also be adopted, which means that repair takes place before the condition intervention level is reached. In the context of a pavement project, this approach could see the treatment of a section of pavement classified as being in need of maintenance.

It is recommended that more than one Do Something strategy is evaluated for each maintenance strategy in order to explore the range of available treatment types. For the Do Something strategies, the required timing of the initial maintenance intervention requires consideration. Options may include

If the latter (deferred) option is selected, then the additional routine maintenance costs need to be included in the lifecycle plan. In the context of a pavement project, the above factors could be realized. For example, a pavement nearing the end of its serviceable life may exhibit surface defects, such as potholes. If the initial treatment is deferred, then there will be an ongoing (possibly increasing) requirement to revisit the site during the period of deferment to carry out repairs to these defects. The costs of these repairs need to be included in the lifecycle plan. If the initial treatment is deferred, then more deterioration may occur to the pavement structure. This may result in a more extensive treatment eventually being required compared to the treatment that would otherwise have been implemented if the site were repaired earlier. By considering a range of treatment strategies and permutations on the type and timing of the initial intervention, an optimal maintenance strategy can be determined.

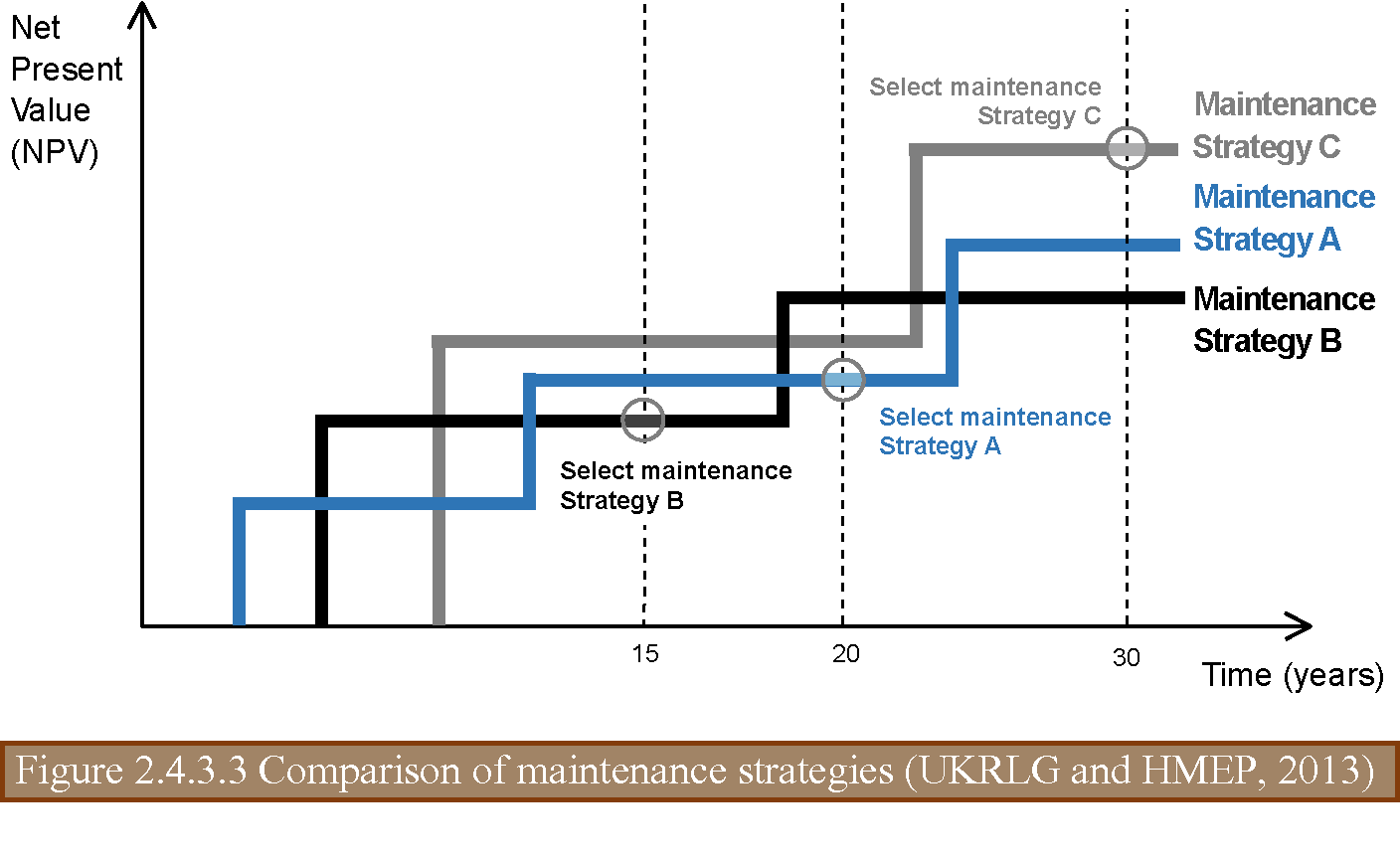

The maintenance strategy with the lowest net present value (NPV) is generally regarded as the most economically beneficial option (see Error: Reference source not found.4). However, whole-life costing is only one factor when selecting a preferred maintenance option. Other factors, such as engineering judgement, network operations, buildability, affordability, and risk management, also require consideration.

An organization may implement the above process according to its skills and capabilities, including data availability and performance models, as follows:

Where insufficient data are available, a more basic approach to lifecycle planning may be sufficient to meet the requirements of the organization. However, even standard approaches require data on asset hierarchy, inventory, and service life (estimated life of the treatment option). This approach may require assumptions to be made based on the experience and local/technical knowledge of the staff involved in the process. This experience and knowledge may include quantum as well as the current and predicted future performance of the asset. Any assumptions need to be documented and any significant risks set out.

A more advanced approach is likely to require higher quality data for performance or deterioration modelling in order to determine the service life of the proposed treatments (as described above). Subsequently, additional investment in data collection and asset management tools may be required in order to analyze and interrogate these data. Where this is the case, the argument should be made for any additional investment based on the benefits and efficiencies that can be obtained through adopting a more advanced approach.

The ability of an organization to develop performance models and model asset deterioration will support the advancement of its approach to lifecycle planning. These models have the capability to predict modes of deterioration and/or failure of the proposed treatment, as well as when the next intervention (the time for the asset to reach the end of its serviceable life) will occur. The approach can be advanced and highly complex approach or simple, depending on the capability of the organization. Two approaches to deterioration may be considered:

Service Life: This describes the life expectancy from construction to the next structural intervention based on industry best practice and local knowledge. This may vary according to traffic or environmental conditions. An organization’s own records of material performance should be a good reference.

Performance modelling: Deterioration profiles for an asset can be determined from a variety of sources, including historical performance, local knowledge, and best practice. Some organizations have developed bespoke deterioration profiles. These can be used for lifecycle planning with more sophisticated approaches to decision support. They will require a significant amount of data and potential calibration, which may be a complex and time consuming activity. These models may be part of the decision support component of the asset management tools (see section 4.1).

The decision-making process to select the investment strategy should align with the approach to asset management and, in particular, provide the most efficient and affordable way of achieving the performance requirements. Typically, the selection of maintenance strategies considers the following:

A number of techniques may be used to select the investment strategy, some of which are listed below. The International Infrastructure Maintenance Manual (IIMM, 2015) also gives advice on these decision-making techniques.

Risk-based evaluation focuses on minimizing the risk associated with the asset through an investment strategy while ensuring that any risks are managed at the minimum cost. The approach to risk management is described in section 2.3. Risk evaluation can be used as a decision-making technique on its own or considered with the other decision support techniques described below.

Whole-life cost is a cost-benefit analysis that quantifies the investment costs, including the cost of the treatment and subsequent maintenance interventions, against economic benefits, including safety, traffic delays, and pollution. These should be assessed for each maintenance strategy. The maintenance strategy with the lowest NPV over the period of analysis provides the lowest whole-life cost. Costs may be determined as described above. Benefits should be determined by each organization and considered in the context of its overall approach to asset management.

Multi-criteria analysis may be used to prioritize competing treatment options from which the maintenance strategy may be selected. A number of criteria may be selected that align with the levels of service and/or goals and objectives of the organization. Typically, these may include safety, serviceability, sustainability, and accessibility. A weighting to demonstrate the relative importance of these factors may be selected from which an overall score is determined. The necessity to meet statutory requirements needs to be reflected in the scoring. This technique can be used where benefits and costs are less tangible to define. However, it supports a qualitative assessment as well as a quantitative one.

The costs selected for any routine maintenance and asset renewal activities should be as reliable as possible. The selection of the maintenance strategy may be sensitive to the accuracy of this information.

A rigorous process should be developed for the collection and recording of cost data for the purposes of lifecycle planning. These cost data may be different from current contract rates because the data take other factors into account, such as overheads. Rates that are used should take into account inflation and be reviewed and updated as more cost information becomes available. The source of all cost data should be referenced.

The build-up of cost data is likely to include a number of assumptions, such as the inclusion of traffic management, contractor’s overheads, project design, and supervision costs. Such information may not be directly available from unit rates, which may be obtained from sources such as term maintenance contracts or framework contracts. Therefore, care needs to be taken in building up the rates in order to understand the item coverage.

The outcome of the lifecycle planning process is an investment strategy for the road infrastructure asset that comprises an asset group and its components and that is affordable and delivers the required performance at the minimum cost. In meeting this outcome, the investment strategy should also support the asset management strategy. A number of iterations, with different maintenance strategies, may be necessary to optimize the investment strategy.

In developing an investment strategy, the following issues should be considered:

What is the level of performance required to maintain a steady state condition and what is the budget required?

Lifecycle plans may be used to demonstrate the investment required to maintain the asset at its current level of performance. This is useful in cases where organizations are satisfied with the performance of their networks and to compare the impact of different funding scenarios.

What is the level of performance that can be achieved with a fixed budget?

Where an organization has fixed funding, lifecycle planning may be used to determine the performance of the asset for the funding allocated. It may also be used to target or prioritize funding in those areas that are most in need and to demonstrate the effect of reduced funding on the performance of assets over the short, medium, and long term.

What is the budget requirement to deliver the performance required?

Organizations can use lifecycle planning to determine future budget requirements. Performance targets may be selected for a hierarchy of asset groups and their components. In doing so, organizations may wish to consider the work needed to sustain the agreed performance requirements and any performance gaps.

What are the cross-asset considerations?

No organization will have unlimited funds to invest in an asset. Cross-asset prioritization, or “trade-off” techniques, may be used to determine where budgets are spent most effectively or at the lowest cost. Consideration of the risk, cost, and performance associated with each asset is key.

What is the timescale?

Lifecycle plans should be prepared for a period of at least 10 years.

Lifecycle plans are essential to assist senior decision makers in developing their financial plans and to substantiate any additional funding needed to achieve the required performance. Equally, they provide evidence of the effect on the asset if funding is not made available and the effect on the consequential future performance of the asset.

When organizations develop maintenance programs (e.g. lifecycle plans), they should ensure that their staff are appropriately trained and have the resources to build sustainable and realistic programs. Organizations should select adequate methods for asset management planning (e.g. lifecycle approach) appropriate to their maturity, needs, and resources.

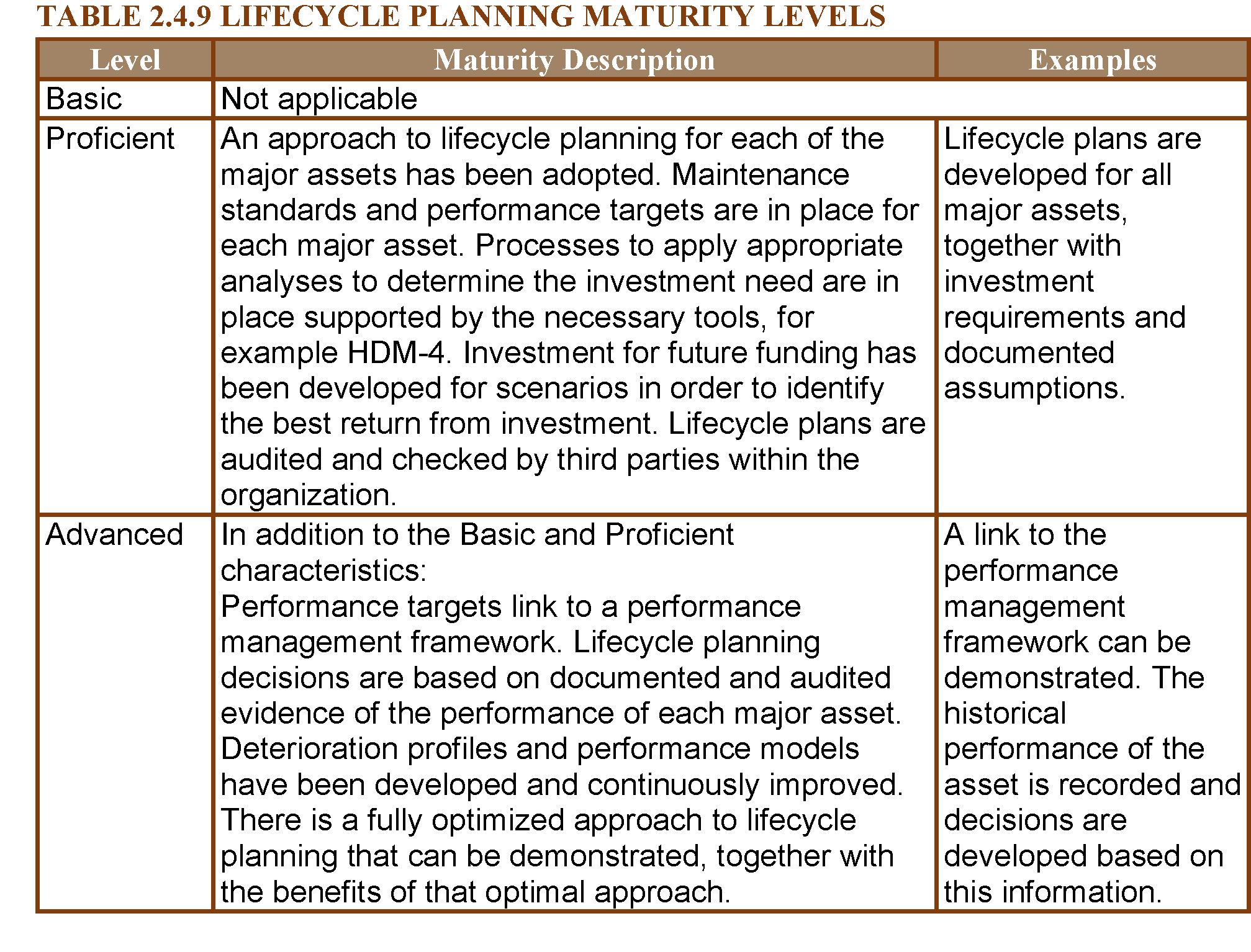

The maturity levels for an organization undertaking lifecycle planning are shown in Table 2.4.9. Organizations may assess their maturity against this scale.

United Kingdom Roads Liaison Group (UKRLG) and Roads Maintenance Efficiency Programme (HMEP) (2013): Road Infrastructure Asset Management Guidance Document. Department for Transport, London. Last accessed July 24, 2015. http://www.ukroadsliaisongroup.org/en/utilities/document-summary.cfm?docid=5C49F48E-1CE0-477F-933ACBFA169AF8CB.

IIMM (2015): IIMM - International Infrastructure Maintenance Manual. IPWEA, Institute of public works Australasia, 5th Edition, Australia, 2015.

HDM-4 (2004): HDM-4 – The Highway Development and Management Series. World Road Association (PIARC/AIPCR), Paris, 2004.

PIARC 2000. Whole Life Costing of Roads – Flexible Pavements, Technical Committee 8 – Flexible Roads, ISBN: 2-94060-119-2 (https://www.piarc.org/ressources/publications/1/3762,08-09-e.pdf).

The following case studies are presented in this chapter:

Case study 1: HDM-4

Case study 2: Life-cycle analysis of Austrian pavements

The Roads Development and Management Tool (HDM-4) is a tool for the analysis, planning, management, and appraisal of road maintenance, improvements, and investment decisions. In 1998, PIARC was assigned the intellectual property s of HDM-4 on behalf of its original stakeholders (HDM-4, 2004). The HDM-4 analytical framework is based on the concept of pavement lifecycle analysis and is applied to predict the following over the lifecycle planning period of a road pavement (typically 15 to 40 years):

The model predicts road deterioration as a function of pavement construction characteristics, traffic loading, and climatic conditions and is directly affected by the standards of maintenance and improvements applied to repair the defects calculated. The long-term condition of the road pavement depends upon the application of these maintenance and improvement standards. Consequently, HDM-4 can determine the costs required to maintain the road to a standard defined by the user within HDM-4. The impacts of the road condition and road design standards on road users are quantified in terms of road user costs, which are made up of the following:

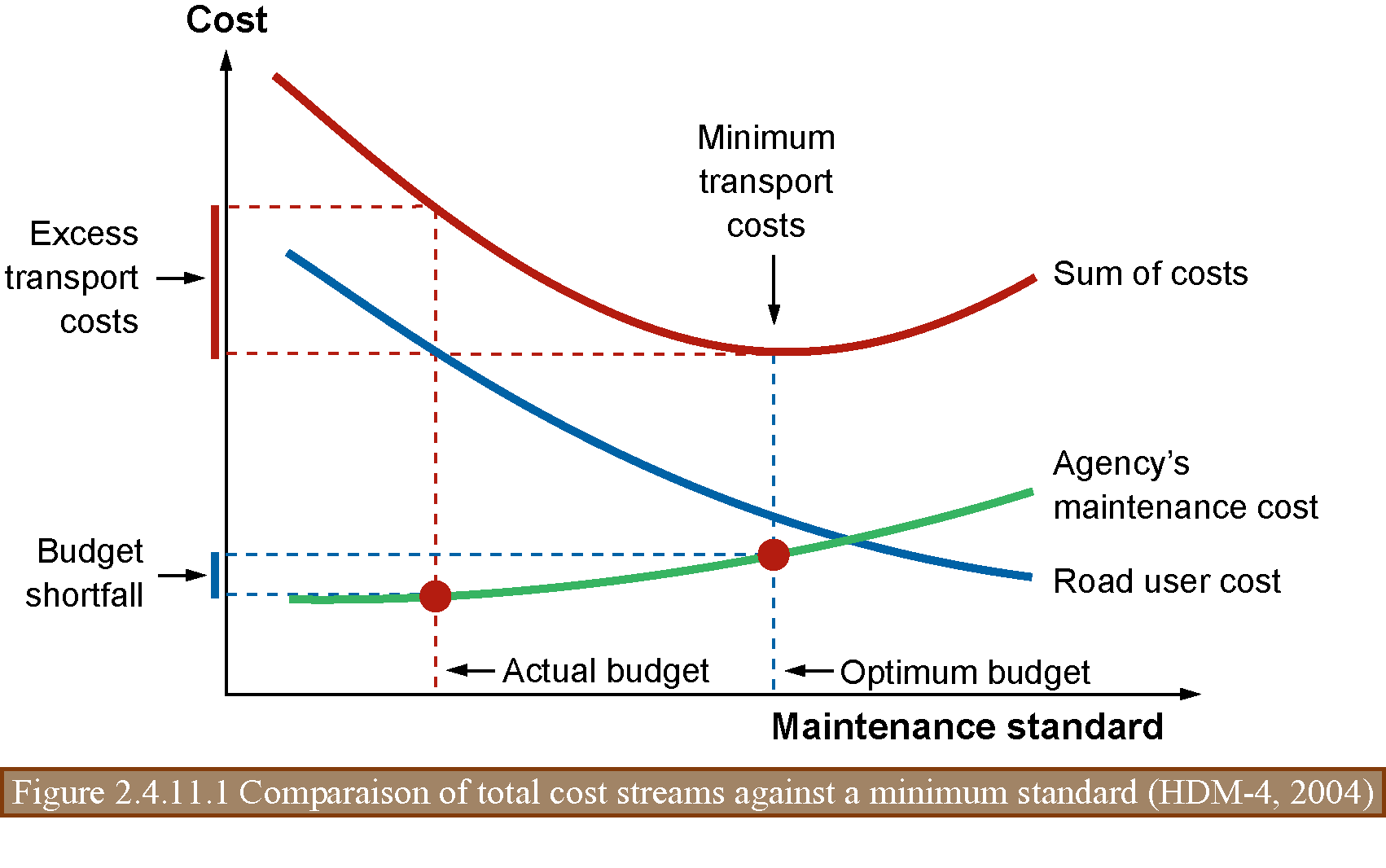

The socioeconomic effects comprise vehicle emissions, energy consumption, and other welfare benefits to the population served by the road network under analysis. HDM-4 is designed to make comparative cost estimates and economic analyses of different investment options or road maintenance strategies. The economic benefit from each road investment strategy is determined by comparing the total cost streams (transportation agency, road user, and socioeconomic costs) against a minimum standard, as illustrated in Figure 2.4.11.1.

HDM-4 can be used in the lifecycle planning process by determining the benefits, costs, economic efficiency, and functional performance of the network by applying different maintenance and improvement standards to the network being analyzed. HDM-4 also allows organizations to determine the most economically efficient maintenance activities to carry out when budgets may not be sufficient to carry out all the work indicated.

ALFRED WENINGER-VYCUDIL, PMS-Consult – Deighton Europe, Austria

The Austrian Pavement Management System is used for a network-wide objective maintenance planning process in consideration of different aspects and demands on different decision levels (project-level, network-level, policy-level). At the moment, it is applied on the whole Federal road network (motorways and expressways) with a total length of more than 2,200 km as well as on the State road network in 7 of 9 Austrian states (Vorarlberg, Tyrol, Salzburg, Styria, Upper Austria, Lower Austria and Burgenland). Furthermore, a similar approach is being used to assess community road pavements and pavements on rural roads in 3 Austrian states.

The system employed for systematic pavement maintenance planning is based on life-cycle cost analysis (LCCA) that provides a framework for decision-making for maintenance measures in order to optimize efficiency in terms of the use of the resources available or in terms of pavement condition. The procedure employs cost-benefit analyses as well as a heuristic optimization process to identify the optimum maintenance treatment strategy in a given set of conditions.

OBJECTIVES

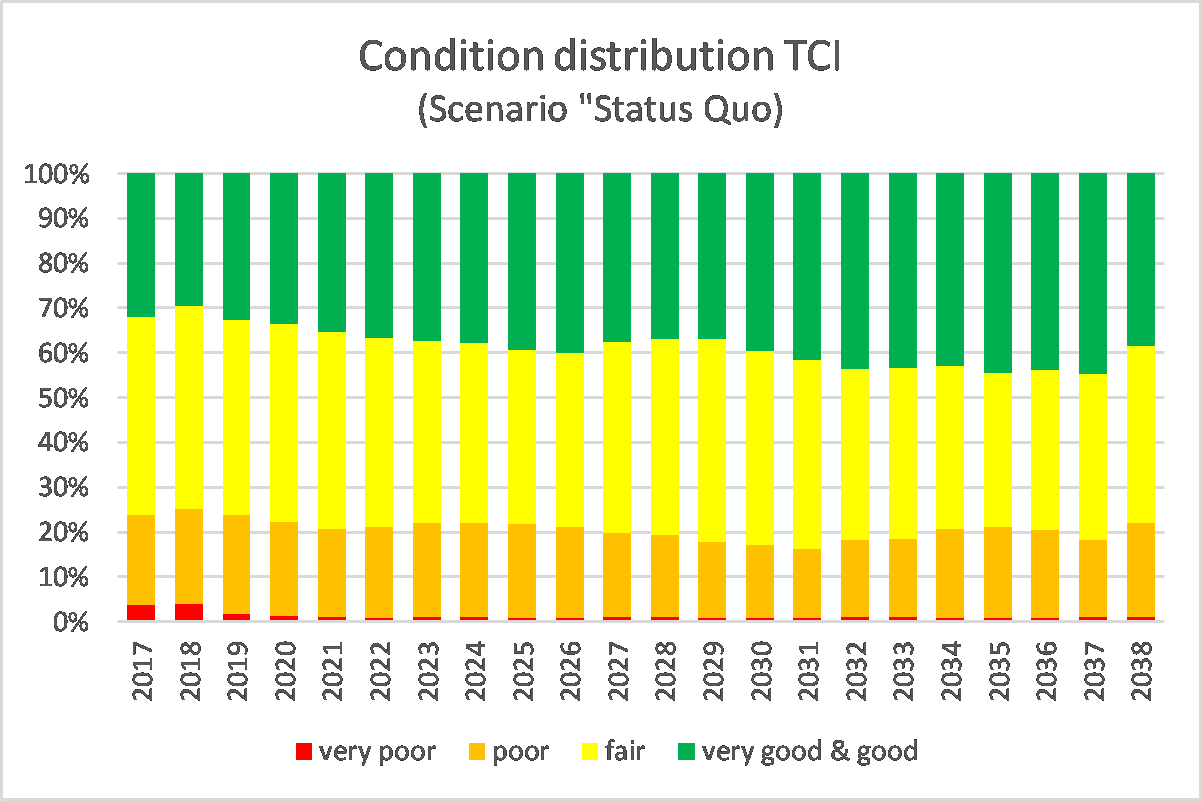

One of the key tasks throughout the decision-making process is the highlighting of needs for maintenance budget for the different assets. This output allows the road administration authorities to clearly show the policy makers the long-term development of the condition distribution of the pavement for different budgets or level of service and also the consequences of reductions in road maintenance funding. The results of the life-cycle analysis include:

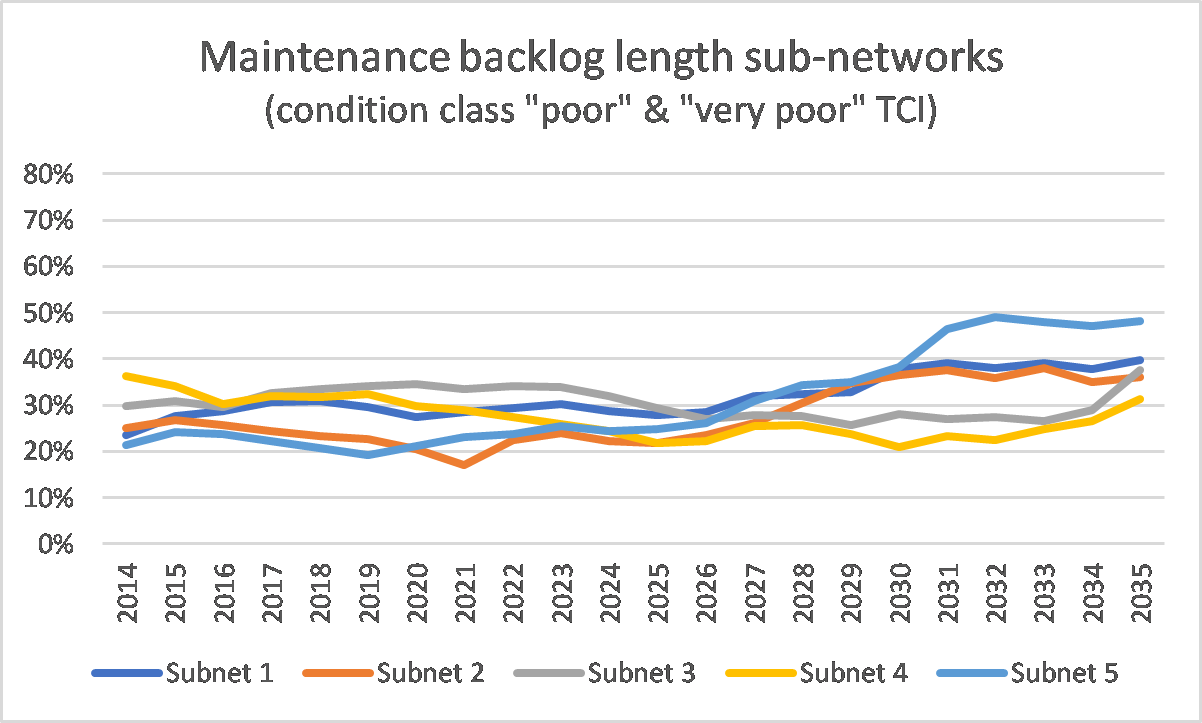

The forecast of future condition using life-cycle analysis is the most efficient way to manage pavements and offers different opportunities for the road administration. The analysis enables the road administration to assess different options in managing their pavements. The assessment of different maintenance treatment strategies on a section level is a comprehensive basis for the definition of the short- to medium-term pavement construction programs. Long-term results allow budget, maintenance and rehabilitation planning and optimization. Phases with high investments can be detected on an early stage and specific investment programs can be prepared in advance.

Advanced systems like the Austrian PMS seek to assess the need for maintenance measures and maintenance funding over a specified period under study or observation on the basis of predictions of pavement performance. The Austrian PMS employs deterministic performance functions for the prediction of pavement performance. These models were derived directly from the data available in the context of different research projects funded by the ASFINAG (motorways and expressways) and the Federal Ministry of Transport, Innovation and Technology (BMVIT) for the state roads.

In the context of PMS analysis, different maintenance relevant data are included as follows:

Since, as a rule, each performance indicator (characteristic) represents only one aspect or one property of the road pavement, the individual dimensional values (technical parameters) obtained for the various characteristics first have to be standardized as dimensionless indices, then aggregated into sub-indices by applying weighting and combination rules, and finally aggregated into an overall index.

For transforming dimensional values, standardization functions (normalization) have been defined which enable an assessment of the damage or defect as a function of the importance of the road section (motorway, expressway, state road). The dimensionless values thus obtained, are aggregated by applying weighting and combination rules to yield a comfort and safety index (CSI) expressing riding safety and riding comfort and into a structural index (SI) which represents the structural capacity of the pavement. The total condition index (TCI) resulting from the sub-indexes can be usedfor calculating the benefit of a maintenance strategy as well as for defining the target function as part of the optimization process.

The result of an analysis is a proposal for an optimum maintenance treatment strategy for each road section analyzed (as a function of the conditions defined), which can be used for further evaluation at project level. By aggregating section-based results, one can also assess developments in terms of cost and pavement conditions across the entire network level and, finally, determine the optimum maintenance requirements. The following two figures show an example of the analysis, where Figure 2.4.11.2 represents a pavement condition distribution and Figure 2.4.11.3 shows the development of the maintenance backlog for different subnetworks in form of a comparison.

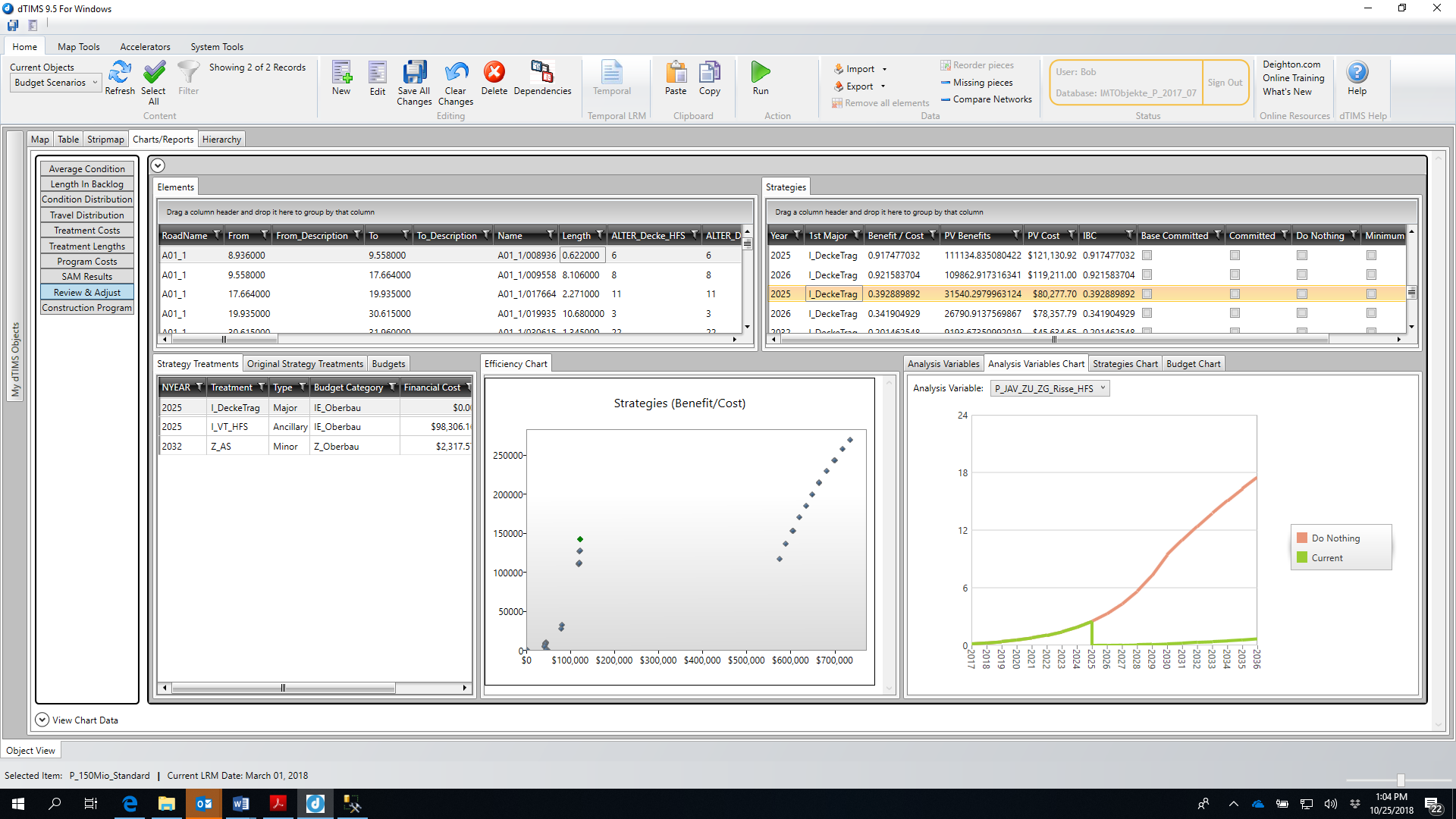

The practical application of the PMS relies on a computer-assisted asset management tool of Canadian origin (dTIMS© - Deighton Total Infrastructure Management System), which employs a deterministic optimization model for selecting the most effective maintenance treatment strategy in the context of life-cycle-cost analysis. In choosing the system, the decisive factor had been that algorithms and models can be modified and defined by the user as necessary to enable effective control or adaptation to the road network and general framework conditions.

Pavement management systems using life-cycle cost analysis have become a standard in many countries around the world over the last 30 years. Beside having an objective instrument for underlining the need for maintenance investments, the solution enables the road administration to model future condition and investment needs for individual roadway segments and for the overall network. Austria is a good example how life-cycle cost analysis has and will be used as technical and strategic planning tool on the different road networks.